Stainless steel strip

STAINLESS STEEL STRIP EN 10088 General applications

| Symbol classification | Numerical | European Standard (EN) | Equivalent | Chemical Composition | |||||||||||||

| General Applications | For springs | AISI | C | Si | Mn | P | S | N | Cr | Cu | Mo | Nb | Ni | Ti | Others | ||

| X2CrTi12 | 1.4512 | EN 10088-2 | - | 409 | ≤ 0.03 | ≤ 1 | ≤ 1 | ≤ 0.04 | ≤ 0.015 | - | 10.50 - 12.50 | - | - | - | - | 6x(C+N) - 0.65 | - |

| X6Cr17 | 1.4016 | EN 10088-2 | EN 10151 | 430 | ≤ 0.08 | ≤ 1 | ≤ 1 | ≤ 0.04 | ≤ 0.015 | - | 16.00 - 18.00 | - | - | - | - | - | - |

| X2CrTiNb18 | 1.4509 | EN 10088-2 | - | 441 | ≤ 0.03 | ≤ 1 | ≤ 1 | ≤ 0.04 | ≤ 0.015 | - | 17.50 - 18.50 | - | - | 3xC+0.30≤Nb≤1.00 | - | 0.10 - 0.60 | - |

| X30Cr13 | 1.4028 | EN 10088-2 | EN 10151 | 420 | 0.26-0.35 | ≤ 1 | ≤ 1.5 | ≤ 0.04 | ≤ 0.015 | - | 12.00 - 14.00 | - | - | - | - | - | - |

| X7CrNiAl17-7 | 1.4568 | EN 10088-2 | EN 10151 | 631 | ≤ 0.09 | ≤ 0.7 | ≤ 1 | ≤ 0.04 | ≤ 0.015 | - | 16.00 - 18.00 | - | - | - | 6.50 - 7.80 | - | Al: 0.70 - 1.50 |

| X10CrNi18-8 | 1.4310 | EN 10088-2 | EN 10151 | 301 | 0.05 - 0.15 | ≤ 2.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.015 | ≤ 0.11 | 16.00 - 19.00 | - | ≤ 0.80 | - | 6.00 - 9.50 | - | - |

| X10CrNi18-8 | 1.4310 Mo | EN 10088-2 | EN 10151 | 301Mo | 0.05 - 0.15 | ≤ 2.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.015 | ≤ 0.11 | 16.00 - 19.00 | - | ≤ 0.80 1) | - | 6.00 - 9.50 | - | - |

| X2CrNi18-9 | 1.4307 | EN 10088-2 | - | 304L | ≤ 0.030 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.015 | ≤ 0.11 | 17.50 - 19.50 | - | - | - | 8.00 - 10.00 | - | - |

| X5CrNi18-10 | 1.4301 | EN 10088-2 | EN 10151 | 304 | ≤ 0.07 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.015 | ≤ 0.11 | 17.00 - 19.50 | - | - | - | 8.00 - 10.50 | - | - |

| X6CrNiTi18-10 | 1.4541 | EN 10088-2 | - | 321 | ≤ 0.08 | ≤ 1.00 | ≤ 2.00 | 0.045 | ≤ 0.015 | - | 17.00 - 19.50 | - | - | - | 9.00 - 12.00 | 5xC - 0.70 | - |

| X5CrNiMo17-12-2 | 1.4401 | EN 10088-2 | EN 10151 | 316 | ≤ 0.070 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.015 | ≤ 0.11 | 16.50 - 18.50 | - | 2.00 - 2.50 | - | 10.00 - 13.00 | - | - |

| X6CrNiMoTi17-12 -2 | 1.4571 | EN 10088-2 | - | 316Ti | ≤ 0.08 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.015 | - | 16.50 - 18.50 | - | 2.00 - 2.50 | - | 10.50 - 13.50 | 5xC - 0.70 | - |

| X2CrNiMo17-12-2 | 1.4404 | EN 10088-2 | - | 316L | ≤ 0.030 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.015 | ≤ 0.10 | 16.50 - 18.50 | - | 2.00 - 2.50 | - | 10.00 - 13.00 | - | - |

| X12CrMnNiN17-7-5 | 1.4372 | EN 10088-2 | EN 10151 | 201 | ≤ 0.15 | ≤ 1.00 | 5.50 - 7.50 | ≤ 0.045 | ≤ 0.015 | 0.05 - 0.25 | 16.00 - 18.00 | - | - | - | 3.50 - 5.50 | - | - |

| X12CrMnNiN18-9-5 | 1.4373 | EN 10088-2 | - | 202 | ≤ 0.15 | ≤ 1.00 | 7.50 - 10.50 | ≤ 0.045 | ≤ 0.015 | 0.05 - 0.25 | 17.00 - 19.00 | - | - | - | 4.00 - 6.00 | - | - |

| X2CrMoTi18-2 | 1.4521 | EN 10088 | - | 444 | ≤ 0.025 | ≤ 1 | ≤ 1 | ≤ 0.04 | ≤ 0.015 | - | 17.00 - 20.00 | - | 1.80 - 2.50 | - | - | - | - |

| X8CrNi25-21 | 1.4845 | EN 10095 | - | 310S | ≤ 0.1 | ≤ 1.5 | ≤ 2 | ≤ 0.045 | ≤ 0.015 | ≤ 0.11 | 24.00 - 26.00 | - | - | - | 19.00 - 22.00 | - | - |

X2CrMoTi18-2 1.4521 and X8CrNi25-21 1.4845 available under a commercial agreement.

1) NB: 3XC+0.30≤NB≤1.00

2) Others: AL: 0,70-1,50

3) Minimum value under commercial agreement. Maximum ≤0.80

SPECIALISTS IN THE SUPPLY OF HIGH QUALITY STAINLESS STEEL STRIP

We are a strip and wire service center specialized in high quality products.

"Our customers rely on VINCO as suppliers of high quality stainless steel strapping, highlighting the flexibility to adapt to their production systems thanks to our cutting capacity in narrow strips and precision tolerances."

Wide availability of stock of stainless steel strip: AISI 430, AISI 420, 420MoV, 409, 441, 631, 301, 301Mo, 304L, 304, 321, 316, 316Ti, 316L, 201, 202, 444, 310S, 440C, 440B and others under commercial consultant.

We offer you stainless steel coils to suit the characteristics of your needs to help you optimise your production:

- Strapping Cutting capacity from 0.10 mm to 5.0 mm thickness and from 3.0 mm to 1.250 mm width.

- Spooling capacity. We have our own lines of reinforcement that allow us to sell straps in coils of up to 2,000 Kg. Minimum internal diameter 300/400 / 500mm maximum outside diameter 760 mm with wooden packing and 1200mm over cardboard core.

- We supply stainless steel strip with different types of edges/borders, at your choice. Strapping with sheared (GK) or special (SK) edges..

- For special edges there is the option of Lamination (with rounded edges) or chip removal (machined edges).

- We can supply you stainless steel strip shaped according to customers's plan.

- We also offer the possibility of supplying inserted and plated strapping.

- Finishes. 2H, 2D, 2B, 2R, 2G, 2J, 1D, 2E, 2K and other stainless steel finishes on request. There is the possibility of supplying tinned or nickel-plated stainless strip under commercial agreement.

- Protections. We offer different types of protections so that our customers receive their coils in an optimal state. Wooden box, wooden lid, cardboard / wood intermediate blocks, plastic / cardboard corners, dustproof plastic bag, VCI moisture-proof paper, VCI moisture-proof plastic, phytosanitary packaging, special packaging for maritime transport, moisture-proof bags and others on request.

Also select the orientation of the coils and the type of pallet when making your inquiry and/or order

Our team of experts is available for any question at (+34) 94 412 33 99 or at the email address info@vinco.es

You may also be interested:

Stainless steel Strop for cutlery

Especially for knives, scissors, blades, razors, spatulas and other cutlery applications.

VINCO offers you special stainless steel strip for cutlery applications, subject to the requirements of the European directives of Food INDUSTRY, RE 1935/2004 and Hexavalent Chromium, ROHS.

See below the usual characteristics and sizes of special stainless strip for the manufacture of knives, scissors, blades, knives, knives, spatulas and other cutlery applications.

| Symbol classification | Numerical classification | European Standard (EN) | Approximate international equivalents | ||

| US (AISI) | Japan (JIS) | China (GB) | |||

| X2CrTi12 | 1.4512 | EN 10088-2 | 409 | SUS409L | - |

| X6Cr17 | 1.4016 | EN 10088-2 | 430 | SUS430 | 10Cr17 |

| X2CrTiNb18 | 1.4509 | EN 10088-2 | 441 | - | - |

| X30Cr13 | 1.4028 | EN 10088-2 | 420 | SUS420J1 | 20Cr13 |

| X7CrNiAl17-7 | 1.4568 | EN 10088-2 | 631 | SUS 631 | 0Cr17Ni7Al |

| X10CrNi18-8 | 1.4310 | EN 10088-2 | 301 | SUS 301 | 1Cr17Ni7 |

| X10CrNi18-8 | 1.4310 Mo | EN 10088-2 | 301Mo | - | - |

| X2CrNi18-9 | 1.4307 | EN 10088-2 | 304L | SUS304L | - |

| X5CrNi18-10 | 1.4301 | EN 10088-2 | 304 | SUS 304 | 0Cr19Ni9 |

| X6CrNiTi18-10 | 1.4541 | EN 10088-2 | 321 | SUS321 | 0Cr18Ni10Ti 1Cr18Ni11Ti H0Cr20Ni10Ti |

| X5CrNiMo17-12-2 | 1.4401 | EN 10088-2 | 316 | SUS 316 | 6Cr17Ni12Mo2 |

| X5CrNiMoTi17-12 -2 | 1.4571 | EN 10088-2 | 316Ti | SUS316Ti | 0Cr18Ni12Mo2Ti 1Cr18Ni12Mo2Ti |

| X2CrNiMo17-12-2 | 1.4404 | EN 10088-2 | 316L | SUS316L | 0Cr18Ni12Mo2Ti 1Cr18Ni12Mo2Ti |

| X12CrMnNiN17-7 -5 | 1.4372 | EN 10088-2 | 201 | SUS201 | - |

| X12CrMnNiN18-9 -5 | 1.4373 | EN 10088-2 | 202 | SUS202 | - |

| X2CrMoTi18-2 | 1.4521 | EN 10088 | 444 | - | - |

| X8CrNi25-21 | 1.4845 | EN 10095 | 310S | SUS310S | 1Cr25Ni20Si2 |

X2CrMoTi18-2 1.4521 and X8CrNi25-21 1.4845 available under a commercial agreement.

EN 10088-2 annealed state/ EN 10151 hardened state

Martensitic steel STRIPs

| Steel designation | Yield strength Rp0.2 | Elongation at break | |||||||||

| Symbol classification | Numerical classification | US (AISI) | State | Hardness | N/mm² min. (leng.) | N/mm² min. (tens.) | Tensile strength Rm N/mm² | A80 mm < 3 mm thick % min (leng. + tens.) | A ≥ 3 mm thick % min. (leng. + tens.) | ||

| Annealed | - | - | 235 HV max. | - | - | 740 max. | 15 | 15 | |||

| X30Cr13 | 1.4028 | 420 | Hardened by cold rolling | +C700 | - | 270-320 HV | - | - | 700 - 850 | - | - |

| +C850 | 1/4 Hard | - | - | 850 - 1000 | - | - | |||||

Ferritic steel STRIPs

| Steel designation | Yield strength Rp0.2 | Elongation at break | |||||||||

| Symbol classification | Numerical classification | US (AISI) | State | Hardness | N/mm² min. (leng.) | N/mm² min. (tens.) | Tensile strength Rm N/mm² | A80 mm < 3 mm thick % min (leng. + tens.) | A ≥ 3 mm thick % min. (leng. + tens.) | ||

| Standardised Types: | |||||||||||

| X2CrTi12 | 1.4512 | 409 | Annealed | - | - | - | 210 | 220 | 380 - 560 | 25 | 25 |

| Annealed | - | - | - | 260 | 280 | 430 - 600 | 20 | 20 | |||

| X6Cr17 | 1.4016 | 430 | Hardened by cold rolling | +C700 | 200 - 300 HV | - | - | 700 - 850 | 2 | - | |

| +C850 | 1/4 Hard | - | - | 850 - 1000 | 1 | - | |||||

| X2CrMoTi18-2 | 1.4521 | 444 | Annealed | - | - | - | 300 | 320 | 420 - 640 | 20 | 20 |

| Special types: | |||||||||||

| X2CrTiNb18 | 1.4509 | 441 | Annealed | - | - | - | 230 | 250 | 430 - 630 | 18 | 18 |

AUSTENITIC STEEL

| Steel designation | Hardness | Yield strength | Tensile strength Rm N/mm² | Elongation at break1) | |||||||

| Symbol classification | Numerical classification | US (AISI) | State | Rp0.2 N/mm² min. (leng.) | Rp1,0 N/mm² min. (tens.) | 1) A80 mm < 3 mm thick % min (leng. + tens.) | 1) A ≥ 3 mm thick % min. (leng. + tens.) | ||||

| Standardised Types: | |||||||||||

| Annealed | - | - | - | 250 | 280 | 600 - 950 | 40 | 40 | |||

| +C850 | 1/4 Hard | - | - | 850 - 1000 | 25 | - | |||||

| +C1000 | 1/2 Hard | - | - | 1000 - 1150 | 20 | - | |||||

| +C1150 | 3/4 Hard | - | - | 1150 - 1300 | 15 | - | |||||

| X10CrNi18-8 | 1.4310 | 301 301Mo | Hardened by cold rolling | +C1300 | 4/4 Hard | 250 - 600 HV | - | - | 1300 - 1500 | 10 | - |

| +C1500 | 5/4 Hard | - | - | 1500 - 1700 | 5 | - | |||||

| +C1700 | K1 | - | - | 1700 - 1900 | 2 | - | |||||

| +C1900 | K2 | - | - | 1900 - 2200 | 1 | - | |||||

| +C2100 | under request | ||||||||||

| X2CrNi18-9 | 1.4307 | 304L | Annealed | - | - | - | 220 | 250 | 520 - 700 | 45 | 45 |

| Annealed | - | - | - | 230 | 260 | 540 - 750 | 45 | 45 | |||

| +C700 | - | - | - | 700-850 | 25 | - | |||||

| X5CrNi18-10 | 1.4301 | 304 | +C850 | 1/4 Hard | - | - | 850-1000 | 12 | - | ||

| Hardened by cold rolling | +C1000 | 1/2 Hard | 220 - 450 HV | - | - | 1000-1150 | 5 | - | |||

| +C1150 | 3/4 Hard | - | - | 1150-1300 | 3 | - | |||||

| +C1300 | 4/4 Hard | - | - | 1300-1500 | 1 | - | |||||

| X6CrNiTi18-10 | 1.4541 | 321 | Annealed | - | - | - | 220 | 250 | 520-720 | 40 | 40 |

| X2CrNiMo17-12-2 | 1.4404 | 316L | Annealed | - | - | - | 240 | 270 | 530 - 680 | 40 | 40 |

| X6CrNiMoTi17-12 -2 | 1.4571 | 316Ti | Annealed | - | - | - | 240 | 270 | 540 - 690 | 40 | 40 |

| Annealed | - | - | - | 240 | 270 | 530 - 680 | 40 | 40 | |||

| +C700 | - | - | - | - | 700 - 850 | 20 | - | ||||

| X5CrNiMo17-12-2 | 14401 | 316 | +C850 | 1/4 Hard | - | - | 850 - 1000 | 10 | - | ||

| Hardened by cold rolling | +C1000 | 1/2 Hard | 220 - 400 HV | - | - | 1000 - 1150 | 4 | - | |||

| +C1150 | 3/4 Hard | - | - | 1150 - 1300 | 1 | - | |||||

| +C1300 | 4/4 Hard | - | - | 1300 - 1500 | - | - | |||||

| Special types: | |||||||||||

| Annealed | - | - | - | 350 | 380 | 680 - 880 | 45 | 45 | |||

| +C850 | 1/4 Hard | - | - | 850 - 1000 | 25 | - | |||||

| X12CrMnNiN17-7 -5 | 1.4372 | 201 | +C1000 | 1/2 Hard | - | - | 1000 - 1150 | 13 | - | ||

| Hardened by cold rolling | +C1150 | 3/4 Hard | 200 - 500 HV | - | - | 1150 - 1300 | 5 | - | |||

| +C1300 | 4/4 Hard | - | - | 1300 - 1500 | 2 | - | |||||

| +C1500 | 5/4 Hard | - | - | 1300 - 1500 | 1 | - | |||||

| X12CrMnNiN18-9 -5 | 1.4373 | 202 | Annealed | - | - | - | 340 | 370 | 680 - 880 | 45 | 45 |

1) Refer to EN 10088-2 / EN 10150 for details of longitudinal or transverse elongation at break type.

PRECIPITATION-HARDENED STEEL

| Steel designation | Hardness | Yield strength Rp0.2 | Tensile strength Rm N/mm² | Elongation at break | |||||||

| Symbol classification | Numerical classification | US (AISI) | State | N/mm² min. (leng.) | N/mm² min. (tens.) | A80 mm < 3 mm thick % min (leng. + tens.) | A ≥ 3 mm thick % min. (leng. + tens.) | ||||

| Annealed | - | - | - | - | - | ≤ 1030 | 19 | 19 | |||

| +C1000 | 1/2 Hard | 300 - 520 HV 1) | - | - | 1000 - 1150 | - | - | ||||

| X7CrNiAl17-7 | 1.4568 | 631 | +C1150 | 3/4 Hard | - | - | 1150 - 1300 | - | - | ||

| Hardened by cold rolling | +C1300 | 4/4 Hard | - | - | 1300 - 1500 | - | - | ||||

| +C1500 | 5/4 Hard | - | - | 1500 - 1700 | - | - | |||||

| +C1700 | K1 | - | - | 1700 - 1900 | - | - | |||||

1) Approximate value.

REFRACTORY STAINLESS STEEL

| Steel designation | Hardness | Yield strength | Tensile strength Rm N/mm² | Elongation at break | |||||||

| Symbol classification | Numerical classification | US (AISI) | State | Rp0,2 N/mm² min. (leng.) | Rp1,0 N/mm² min. (tens.) | A80 mm < 3 mm thick % min (leng. + tens.) | A ≥ 3 mm thick % min. (leng. + tens.) | ||||

| X8CrNi25-21 | 1.4845 | 310S | Annealed | - | - | 192 HB max. | 210 | - | 500 - 700 | 33 | 35 |

X2CrMoTi18-2 1.4521 and X8CrNi25-21 1.4845 available under a commercial agreement.

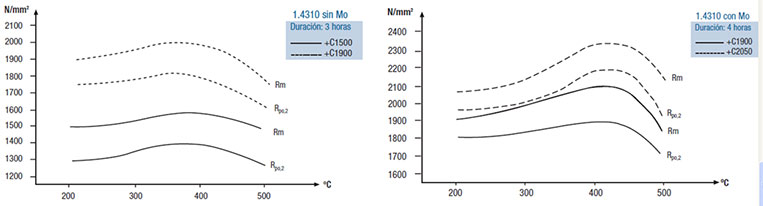

Charts for guidance purposes for STABILISATION (TEMPERING) CONDITIONS

TYPE OF PROCESS ROUTE AND SURFACE FINISH OF PLATES AND COILS EN 10088-2 1)

| COLD ROLLING | ||||

| Abbreviation | Type of process route | Surface finish | Remarks | AISI |

| 2H | Hardened by cold forming | Bright | Hardened by cold forming, to obtain the highest level of mechanical strength. | TR |

| 2D | Cold-rolled, heat treated, pickled | Smooth | Finish with good ductility, but not as smooth as 2B or 2R. | 2D |

| 2B | Cold-rolled, heat treated, pickled and skin passed | Smoother than 2D | Normal finish for most steels. Ensures good corrosion resistance, smoothness and flatness. Also common for subsequent processes. Skin passing can be replaced by tension levelling. | 2B |

| 2R | Cold-rolled, bright annealed | Smooth, bright and reflective | Smoother and brighter finish than 2B. Also common for subsequent processing. | BA |

| 2G | Ground | Can be specified based on the grain size of the grinding wheel or surface roughness. It has a unidirectional texture, not very reflective. | 3 | |

| 2J | Brushed or polished matt | Smother than when ground 1) | The brushing grade, type of abrasive belt and surface roughness can be specified. It has a unidirectional texture, not very reflective. | 6 |

| 1D | Hot rolled, heat treated, pickled | Free of scale | Normal finish for most steels in order to ensure good corrosion resistance; A finish that is also common for products that are going to undergo subsequent processing. Grinding marks permitted. Coarser finish than 2D or 2B. | 1 |

| 2E | Cold-rolled, heat treated, mechanically descaled | Rough and matt | Generally applied to steel with pickling-resistant scale. Can be followed by pickling. | 1 |

| 2K | Gloss polished | 1) | Additional specific requirements to a "J" type finish, in order to achieve adequate corrosion resistance in marine environments and for external architectural applications. They are finishes with a transverse roughness of Ra<0.5µm and with a clean surface appearance. | 4 |

1) Within the description of each finish, the properties may vary and further details may be necessary to correctly specify the desired finish (for example, the abrasive grain or surface roughness).

Tinned or nickel plated strips can be supplied under a commercial agreement.

AVERAGE SURFACE ROUGHNESS EN 10151:2002

- Ra < 0.3 µm for tensile strength levels of +C1150 and above.

- Ra < 0.5 µm for tensile strength levels ranging from +C700 to +C1000.

STAINLESS STEEL STRIP THICKNESS TOLERANCES

| Specified thickness t | Thickness tolerance specified according to EN ISO 9445-1 for a nominal width of | ||||||||

| w < 125 | 125 ≤ w < 250 | 250 ≤ w < 600 | |||||||

| Normal | Fine (F) | Precision (P) | Normal | Fine (F) | Precision (P) | Normal | Fine (F) | Precision (P) | |

| 0.05 ≤ t < 0.10 | ± 0.10 t | ± 0.06 t | ± 0.04 t | ± 0.12 t | ± 0.10 t | ± 0.08 t | ± 0.15 t | ± 0.10 t | ± 0.08 t |

| 0.10 ≤ t < 0.15 | ± 0.010 | ± 0.008 | ± 0.006 | ± 0.015 | ± 0.012 | ± 0.008 | ± 0.020 | ± 0.015 | ± 0.010 |

| 0.15 ≤ t < 0.20 | ± 0.015 | ± 0.010 | ± 0.008 | ± 0.020 | ± 0.012 | ± 0.010 | ± 0.025 | ± 0.015 | ± 0.012 |

| 0.20 ≤ t < 0.25 | ± 0.015 | ± 0.012 | ± 0.008 | ± 0.020 | ± 0.015 | ± 0.010 | ± 0.025 | ± 0.020 | ± 0.012 |

| 0.25 ≤ t < 0.30 | ± 0.017 | ± 0.012 | ± 0.009 | ± 0.025 | ± 0.015 | ± 0.012 | ± 0.030 | ± 0.020 | ± 0.015 |

| 0.30 ≤ t < 0.40 | ± 0.020 | ± 0.015 | ± 0.010 | ± 0.025 | ± 0.020 | ± 0.012 | ± 0.030 | ± 0.025 | ± 0.015 |

| 0.40 ≤ t < 0.50 | ± 0.025 | ± 0.020 | ± 0.012 | ± 0.030 | ± 0.020 | ± 0.015 | ± 0.035 | ± 0.025 | ± 0.018 |

| 0.50 ≤ t < 0.60 | ± 0.030 | ± 0.020 | ± 0.014 | ± 0.030 | ± 0.025 | ± 0.015 | ± 0.040 | ± 0.030 | ± 0.020 |

| 0.60 ≤ t < 0.80 | ± 0.030 | ± 0.025 | ± 0.015 | ± 0.035 | ± 0.030 | ± 0.018 | ± 0.040 | ± 0.035 | ± 0.025 |

| 0.80 ≤ t < 1.00 | ± 0.030 | ± 0.025 | ± 0.018 | ± 0.040 | ± 0.030 | ± 0.020 | ± 0.050 | ± 0.035 | ± 0.025 |

| 1.00 ≤ t < 1.20 | ± 0.035 | ± 0.030 | ± 0.020 | ± 0.045 | ± 0.035 | ± 0.025 | ± 0.050 | ± 0.040 | ± 0.030 |

| 1.20 ≤ t < 1.50 | ± 0.040 | ± 0.030 | ± 0.020 | ± 0.050 | ± 0.035 | ± 0.025 | ± 0.060 | ± 0.045 | ± 0.030 |

| 1.50 ≤ t < 2.00 | ± 0.050 | ± 0.035 | ± 0.025 | ± 0.060 | ± 0.040 | ± 0.030 | ± 0.070 | ± 0.050 | ± 0.035 |

| 2.00 ≤ t < 2.50 | ± 0.050 | ± 0.035 | ± 0.025 | ± 0.070 | ± 0.045 | ± 0.030 | ± 0.080 | ± 0.060 | ± 0.040 |

| 2.50 ≤ t ≤ 3.00 | ± 0.060 | ± 0.045 | ± 0.030 | ± 0.070 | ± 0.050 | ± 0.035 | ± 0.090 | ± 0.070 | ± 0.045 |

Measurements in mm.

B) Thickness tolerances for strips cut from standard material.

| Nominal thickness t | Normal tolerances for nominal width w | Close tolerances (S) for a nominal width w | ||||

| w ≤ 1000 | 1000 < w ≤ 1300 | 1300 < w ≤ 2100 | w ≤ 1000 | 1000 < w ≤ 1300 | 1300 < w ≤ 2100 | |

| t < 0.30 | ± 0.030 | - | - | ± 0.020 | - | - |

| 0.30 ≤ t < 0.50 | ± 0.040 | ± 0.040 | - | ± 0.025 | ± 0.030 | - |

| 0.50 ≤ t < 0.60 | ± 0.045 | ± 0.050 | - | ± 0.030 | ± 0.035 | - |

| 0.60 ≤ t < 0.80 | ± 0.050 | ± 0.050 | - | ± 0.035 | ± 0.040 | - |

| 0.80 ≤ t < 1.00 | ± 0.055 | ± 0.060 | ± 0.07 | ± 0.040 | ± 0.045 | ± 0.050 |

| 1.00 ≤ t < 1.20 | ± 0.060 | ± 0.070 | ± 0.08 | ± 0.045 | ± 0.045 | ± 0.060 |

| 1.20 ≤ t < 1.50 | ± 0.070 | ± 0.080 | ± 0.10 | ± 0.050 | ± 0.055 | ± 0.060 |

| 1.50 ≤ t < 2.00 | ± 0.080 | ± 0.090 | ± 0.11 | ± 0.055 | ± 0.060 | ± 0.070 |

| 2.00 ≤ t < 2.50 | ± 0.090 | ± 0.10 | ± 0.13 | - | - | - |

| 2.50 ≤ t ≤ 3.00 | ± 0.11 | ± 0.12 | ± 0.15 | - | - | - |

| 3.00 ≤ t ≤ 4.00 | ± 0.13 | ± 0.14 | ± 0.16 | - | - | - |

| 4.00 ≤ t ≤ 5.00 | ± 0.14 | ± 0.15 | ± 0.19 | - | - | - |

Measurements in mm.

WIDTH TOLERANCES

| Specified thickness t | Standard slitting tolerances for VINCO 1) | Specified width w according to EN ISO 9445-1 5) | ||||||||||||||

| 3-15 | 15-50 | 50-150 | >150 | w ≤ 40 | 40 < w ≤ 125 | 125 < w ≤ 250 | 250 < w ≤ 600 | |||||||||

| Normal | Fine (F) | Precision (P) | Normal | Fine (F) | Precision (P) | Normal | Fine (F) | Precision (P) | Normal | Fine (F) | Precision (P) | |||||

| t < 0,25 | 0;+0,15 | 0;+0,15 | 0;+0,15 | 0;+0,2 | 0;+0,17 | 0;+0,13 | 0;+0,10 | 0;+0,20 | 0;+0,15 | 0;+0,12 | 0;+0,25 | 0;+0,20 | 0;+0,15 | 0;+0,50 | 0;+0,50 | 0;+0,40 |

| 0,25 ≤ t < 0,40 | 0;+0,15 | 0;+0,15 | 0;+0,15 | 0;+0,2 | 0;+0,20 | 0;+0,15 | 0;+0,12 | 0;+0,25 | 0;+0,20 | 0;+0,15 | 0;+0,30 | 0;+0,22 | 0;+0,17 | 0;+0,60 | 0;+0,50 | 0;+0,40 |

| 0,40 ≤ t < 0,50 | 0;+0,17 | 0;+0,18 | 0;+0,2 | 0;+0,24 | 0;+0,20 | 0;+0,15 | 0;+0,12 | 0;+0,25 | 0;+0,22 | 0;+0,15 | 0;+0,30 | 0;+0,22 | 0;+0,17 | 0;+0,60 | 0;+0,50 | 0;+0,40 |

| 0,50 ≤ t < 1 | 0;+0,17 2) | 0;+0,18 2) | 0;+0,20 2) | 0;+0,242) | 0;+0,25 | 0;+0,22 | 0;+0,15 | 0;+0,25 | 0;+0,22 | 0;+0,17 | 0;+0,40 | 0;+0,25 | 0;+0,20 | 0;+0,70 | 0;+0,60 | 0;+0,50 |

| 1 ≤ t < 1,50 | 0;+0,20 3) | 0;+0,2 3) | 0;+0,20 3) | 0;+0,3 3) | 0;+0,25 | 0;+0,22 | 0;+0,15 | 0;+0,30 | 0;+0,25 | 0;+0,17 | 0;+0,50 | 0;+0,30 | 0;+0,22 | 0;+1,0 | 0;+0,70 | 0;+0,60 |

| 1,50 ≤ t < 2,50 | As per request | 0;+0,26 4) | 0;+0,30 4) | 0;+0,32 4) | - | - | - | 0;+0,40 | 0;+0,25 | 0;+0,20 | 0;+0,60 | 0;+0,40 | 0;+0,25 | 0;+1,0 | 0;+0,80 | 0;+0,60 |

| 2,5 ≤ t ≤ 3 | As per request | As per request | 0;+0,32 | 0;+0,35 | - | - | - | 0;+0,50 | 0;+0,30 | 0;+0,25 | 0;+0,60 | 0;+0,40 | 0;+0,25 | 0;+1,2 | 0;+1,0 | 0;+ 0,90 |

| 3 < t ≤ 5 | As per request | As per request | 0;+0,32 | 0;+0,35 | - | - | - | - | - | - | - | - | - | - | - | - |

Measurements in mm.

1) Other, closer dimensional tolerances are possible under a commercial agreement.

2) Including the value t=1

3) Including the value t=1,5

4) Including the value t=2,5

5) Subject to an agreement, the tolerance can be equal in ± or all -. In both cases, the total tolerance range must be as shown in the table.

EDGE CAMBER TOLERANCES

| Nominal width (W) | Closer edge curve tolerances possible under a commercial agreement. | Edge curve tolerances 1) for average lengths of | ||

| Maximum deviation 2000 mm Thickness (t) | Maximum deviation 2000 mm Thickness (t) | |||

| t ≤ 1.20 mm | t > 1.20 mm | Normal | Close ( R ) | |

| 3 ≤ W < 6 | 10,00 | 15,00 | - | - |

| 6 < W ≤ 10 | 8,00 | 12,00 | - | - |

| 10 < W ≤ 20 | 4,00 | 6,00 | 16 2) | 6 |

| 20 < W < 25 | 2,00 | 4,00 | 16 | 6 |

| 25 ≤ W < 40 | 2,00 | 4,00 | 12 | 5 |

| 40 ≤ W < 125 | 2,00 | 4,00 | 8 | 4 |

| 125 ≤ W < 350 | 2,00 | 4,00 | 6 | 3 |

| 350 ≤ W < 600 | - | - | - | - |

Measurements in mm.

1) Edge curve tolerances for cold-rolled strips and for strips in cut lengths obtained from cold-rolled strips according to EN ISO 9445.

2) For nominal widths of 10mm included.

| ± 0,08 |

The global electric vehicle (EV) market is experiencing significant growth, driven by a number of...

The global electric vehicle (EV) market is experiencing significant growth, driven by a number of...