Hard Drawn Steel Wire

HARD DRAWN STEEL WIRE - CHEMICAL COMPOSITION, MASS % EN 10270-1:2011

| Chemical composition % | |||||||

| Designation | European Standard (EN) | C | Si | Mn | Max. P | Max. S | Max. Cu |

| SL | EN 10270-1 | 0.35 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.035 | 0.035 | 0.20 |

| SM | EN 10270-1 | 0.35 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.035 | 0.035 | 0.20 |

| SH | EN 10270-1 | 0.35 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.035 | 0.035 | 0.20 |

| DM | EN 10270-1 | 0.45 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.020 | 0.025 | 0.12 |

| DH | EN 10270-1 | 0.45 - 1.00 | 0.10 - 0.30 | 0.40 - 1.20 | 0.020 | 0.025 | 0.12 |

| CLASS II | DIN 17223:1964-1 | values not guaranteed | 0.030 | 0.030 | 0.12 | ||

Note- For diameters ≥ 1.6mm , the hard drawn steel wire can be supplied using patented or unpatented lead material.

HARD DRAWN STEEL WIRE: MECHANICAL STRENGTH AND TOUGHNESS

SPECIFICATIONS AND FINISHES

At VINCO we are specialists in the supply of wire and we have three types: round, square and flat wire. In addition, you can also order wire rod according to you r needs. Consult the capacities section where the measurements and images of each one of them are specified.

The chemical composition of the different drawn steel wires available in our catalogue is governed by the EN 10270-1:2011 standard, which refers to steel wires for mechanical springs. The products we supply from VINCO are mainly focused on stamping and electrocomponent parts, as well as works related to the automotive sector and other general applications.

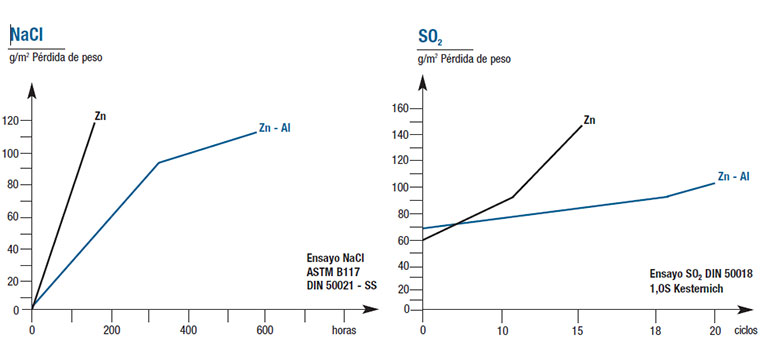

Hard drawn steel wire has several coating options, which are listed in the standard: phosphated, galvanised, zinc-aluminium, reddish and copper. For the zinc-aluminium coating, the minimum coating masses depending on the nominal diameter of the drawn wire are defined in the finishing section of the product data sheet. In addition, salt spray tests are also carried out to test the materials against corrosion under extreme conditions, especially in coastal environments. In this test, the exposure period has been taken into account to determine the minimum coating mass in the case of galvanised and zinc-aluminium coating. The latter has a corrosion resistance 2-3 times higher than the zinc coating (in a fog test and in a S02 atmosphere).

In addition to the coatings listed in the Standard, VINCO offers you other options so that you can apply them in different conditions: tin plating, brass plating, electro-zinc plating, nickel plating and plastic plating in different colours.

TYPES OF PACKAGING AND SUPPLY FOR DRAWN WIRE

The packaging options we have available for drawn wire are specified, together with the maximum weight in kg, in the following table:

| Packaging format | Maximum weight in kg |

| Roll | 500 |

| Z-coil with horizontal or vertical axis orientation | 800 |

| Plastic reel DIN 300 | 17 |

| Plastic reel DIN 355 | 45 |

| Metallic reel DIN 560 G200/32 | 150 |

| Metallic reel G240/40 | 300 |

| Metallic reel DIN 760 G280/40 | 400 |

| Metallic reel G360/40 | 450 |

| Wooden reel G240/40 | 300 |

| Wooden reel G360/40 | 300 |

| Rods | - |

In addition to the type of packaging, we offer different supply possibilities to adapt to the needs of each customer, such as the type of palletisation - square or round - and the orientation of the axis of the reels - horizontal or vertical axis. Along with these packaging and supply options, at VINCO we have different protection elements to preserve all the properties of our wires during the shipping process: lid, VCI damp-proof paper, VCI damp-proof plastic, phytosanitary packaging, maritime packaging and damp-proof sacks.

Consult our team of professionals to resolve any doubts or queries you may have: write to us at info@vinco.es or call (+34) 94 412 33 99. We will be delighted to help you!

APPROXIMATE EQUIVALENTS

| EUROPEAN | AMERICAN | JAPANESE | CHINESE | ||

| DESIGNATION | EN STANDARD | DIN | ASTM | G-3506 / G3522 | GB / T 4357 |

| SL | EN 10270-1 | CLASS A | A 227 | SWB | SL |

| SM | EN 10270-1 | CLASS B | A 227 | SWC | SM |

| SH | EN 10270-1 | CLASS C | A 228 | SWP-B | SH |

| DM | EN 10270-1 | - | A 227 | - | - |

| DH | EN 10270-1 | CLASS D | A 228 | SWP-B | DH |

| CLASS II | DIN 17223:1964-1 | CLASS II | - | - | - |

APPLICATION OF HARD DRAWN STEEL WIRE

| TYPE | Application of Hard Drawn Steel Wire |

| SL | Tension, compression or torsion springs that are chiefly subjected to low static stress. |

| SM | Tension, compression or torsion springs that are subjected to medium-high static stresses or, rarely, dynamic stresses. |

| DM | Tension, compression or torsion springs that are subjected to medium-high dynamic stresses. Also for wire shapes that require severe bending. |

| SH | Tension, compression or torsion springs that are subjected to high static stresses or moderately dynamic stresses. |

| DH | Tension, compression and torsion springs that are mainly submitted to high static strains and to medium levels of dynamic strains. |

| CLASS II | Compression springs, extension springs,and torsion springs for high and dynamic stresses. |

Types of wires for springs. Classed according to EN 10270-1:

| Tensile strength | Static conditions | Dynamic conditions |

| Low | SL | - |

| Medium | SM | DM |

| High | SH | DH |

MECHANICAL PROPERTIES AND QUALITY REQUIREMENTS OF THE SL, SM, DM, SH AND DH STEEL WIRE TYPES EN 10270-1

| Diameter of the wire d | Tensile strength Rm For steel wires of the type | CLASS II (approx.) 1) | Minimum area reduction after Z break for SL, SM, SH, DM and DH wire types | ||||

| Nominal value mm | SL | SM | DM | SH | DH e | ||

| MPa | MPa | MPa | MPa | MPa | % | ||

| d = 0.05 | - | - | - | - | 2800 - 3520 | ||

| 0.05 < d ≤ 0.06 | - | - | - | - | 2800 - 3520 | ||

| 0.06 < d ≤ 0.07 | - | - | - | - | 2800 - 3520 | ||

| 0.07 < d ≤ 0.08 | - | - | - | - | 2800 - 3480 | ||

| 0.08 < d ≤ 0.09 | - | - | - | - | 2800 - 3430 | ||

| 0.09 < d ≤ 0.10 | - | - | - | - | 2800 - 3380 | ||

| 0.10 < d ≤ 0.11 | - | - | - | - | 2800 - 3350 | ||

| 0.11 < d ≤ 0.12 | - | - | - | - | 2800 - 3320 | 2700 - 3090 | |

| 0.12 < d ≤ 0.14 | - | - | - | - | 2800 - 3250 | ||

| 0.14 < d ≤ 0.16 | - | - | - | - | 2800 - 3200 | ||

| 0.16 < d ≤ 0.18 | - | - | - | - | 2800 - 3160 | ||

| 0.18 < d ≤ 0.20 | - | - | - | - | 2800 - 3110 | ||

| 0.20 < d ≤ 0.22 | - | - | - | - | 2770 - 3080 | ||

| 0.22 < d ≤ 0.25 | - | - | - | - | 2770 - 3010 | ||

| 0.25 < d ≤ 0.28 | - | - | - | - | 2680 - 2970 | ||

| 0.28 < d ≤ 0.30 | - | 2370 - 2650 | 2370 - 2650 | 2660 - 2940 | 2660 - 2940 | ||

| 0.30 < d ≤ 0.32 | - | 2350 - 2630 | 2350 - 2630 | 2640 - 2920 | 2640 - 2920 | ||

| 0.32 < d ≤ 0.34 | - | 2330 - 2600 | 2330 - 2600 | 2610 - 2890 | 2610 - 2890 | ||

| 0.34 < d ≤ 0.36 | - | 2310 - 2580 | 2310 - 2580 | 2590 - 2870 | 2590 - 2870 | 2650 - 3040 | |

| 0.36 < d ≤ 0.38 | - | 2290 - 2560 | 2290 - 2560 | 2570 - 2850 | 2570 - 2850 | ||

| 0.38 < d ≤ 0.40 | - | 2270 - 2550 | 2270 - 2550 | 2560 - 2830 | 2560 - 2830 | ||

| 0.40 < d ≤ 0.43 | - | 2250 - 2520 | 2250 - 2520 | 2530 - 2800 | 2530 - 2800 | ||

| 0.43 < d ≤ 0.45 | - | 2240 - 2500 | 2240 - 2500 | 2510 - 2780 | 2510 - 2780 | ||

| 0.45 < d ≤ 0.48 | - | 2220 - 2480 | 2220 - 2480 | 2490 - 2760 | 2490 - 2760 | 2650 - 2940 | |

| 0.48 < d ≤ 0.50 | - | 2200 - 2470 | 2200 - 2470 | 2480 - 2740 | 2480 - 2740 | ||

| 0.50 < d ≤ 0.53 | - | 2180 - 2450 | 2180 - 2450 | 2460 - 2720 | 2460 - 2720 | ||

| 0.53 < d ≤ 0.56 | - | 2170 - 2430 | 2170 - 2430 | 2440 - 2700 | 2440 - 2700 | ||

| 0.56 < d ≤ 0.60 | - | 2140 - 2400 | 2140 - 2400 | 2410 - 2670 | 2410 - 2670 | ||

| 0.60 < d ≤ 0.63 | - | 2130 - 2380 | 2130 - 2380 | 2390 - 2650 | 2390 - 2650 | 2550 - 2840 | |

| 0.63 < d ≤ 0.65 | - | 2120 - 2370 | 2120 - 2370 | 2380 - 2640 | 2380 - 2640 | ||

| 0.65 < d ≤ 0.70 | - | 2090 - 2350 | 2090 - 2350 | 2360 - 2610 | 2360 - 2610 | ||

| 0.70 < d ≤ 0.75 | - | 2070 - 2320 | 2070 - 2320 | 2330 - 2580 | 2330 - 2580 | ||

| 0.75 < d ≤ 0.80 | - | 2050 - 2300 | 2050 - 2300 | 2310 - 2560 | 2310 - 2560 | 40 | |

| 0.80 < d ≤ 0.85 | - | 2030 - 2280 | 2030 - 2280 | 2290 - 2530 | 2290 - 2530 | 2500 - 2800 | 40 |

| 0.85 < d ≤ 0.90 | - | 2010 - 2260 | 2010 - 2260 | 2270 - 2510 | 2270 - 2510 | 40 | |

| 0.90 < d ≤ 0.95 | - | 2000 - 2240 | 2000 - 2240 | 2250 - 2490 | 2250 - 2490 | 40 | |

| 0.95 < d ≤ 1.00 | 1720 - 1970 | 1980 - 2220 | 1980 - 2220 | 2230 - 2470 | 2230 - 2470 | 40 | |

| 1.00 < d ≤ 1.05 | 1710 - 1950 | 1960 - 2200 | 1960 - 2200 | 2210 - 2450 | 2210 - 2450 | 2450 - 2750 | 40 |

| 1.05 < d ≤ 1.10 | 1690 - 1940 | 1950 - 2190 | 1950 - 2190 | 2200 - 2430 | 2200 - 2430 | 40 | |

| 1.10 < d ≤ 1.20 | 1670 - 1910 | 1920 - 2160 | 1920 - 2160 | 2170 - 2400 | 2170 - 2400 | 40 | |

| 1.20 < d ≤ 1.25 | 1660 - 1900 | 1910 - 2140 | 1910 - 2140 | 2150 - 2380 | 2150 - 2380 | 40 | |

| 1.25 < d ≤ 1.30 | 1640 - 1890 | 1900 - 2130 | 1900 - 2130 | 2140 - 2370 | 2140 - 2370 | 2350 - 2650 | 40 |

| 1.30 < d ≤ 1.40 | 1620 - 1860 | 1870 - 2100 | 1870 - 2100 | 2110 - 2340 | 2110 - 2340 | 40 | |

| 1.40 < d ≤ 1.50 | 1600 - 1840 | 1850 - 2080 | 1850 - 2080 | 2090 - 2310 | 2090 - 2310 | 40 | |

| 1.50 < d ≤ 1.60 | 1590 - 1820 | 1830 - 2050 | 1830 - 2050 | 2060 - 2290 | 2060 - 2290 | 2260 - 2500 | 40 |

| 1.60 < d ≤ 1.70 | 1570 - 1800 | 1810 - 2030 | 1810 - 2030 | 2040 - 2260 | 2040 - 2260 | 40 | |

| 1.70 < d ≤ 1.80 | 1550 - 1780 | 1790 - 2010 | 1790 - 2010 | 2020 - 2240 | 2020 - 2240 | 2210 - 2450 | 40 |

| 1.80 < d ≤ 1.90 | 1540 - 1760 | 1770 - 1990 | 1770 - 1990 | 2000 - 2220 | 2000 - 2220 | 40 | |

| 1.90 < d ≤ 2.00 | 1520 - 1750 | 1760 - 1970 | 1760 - 1970 | 1980 - 2200 | 1980 - 2200 | 2110 - 2350 | 40 |

| 2.00 < d ≤ 2.10 | 1510 - 1730 | 1740 - 1960 | 1740 - 1960 | 1970 - 2180 | 1970 - 2180 | 40 | |

| 2.10 < d ≤ 2.25 | 1490 - 1710 | 1720 - 1930 | 1720 - 1930 | 1940 - 2150 | 1940 - 2150 | 40 | |

| 2.25 < d ≤ 2.40 | 1470 - 1690 | 1700 - 1910 | 1700 - 1910 | 1920 - 2130 | 1920 - 2130 | - | 40 |

| 2.40 < d ≤ 2.50 | 1460 - 1680 | 1690 - 1890 | 1690 - 1890 | 1900 - 2110 | 1900 - 2110 | 40 | |

| 2.50 < d ≤ 2.60 | 1450 - 1660 | 1670 - 1880 | 1670 - 1880 | 1890 - 2100 | 1890 - 2100 | 40 | |

| 2.60 < d ≤ 2.80 | 1420 - 1640 | 1650 - 1850 | 1650 - 1850 | 1860 - 2070 | 1860 - 2070 | - | 40 |

| 2.80 < d ≤ 3.00 | 1410 - 1620 | 1630 - 1830 | 1630 - 1830 | 1840 - 2040 | 1840 - 2040 | - | 40 |

| 3.00 < d ≤ 3.20 | 1390 - 1600 | 1610 - 1810 | 1610 - 1810 | 1820 - 2020 | 1820 - 2020 | - | 40 |

| 3.20 < d ≤ 3.40 | 1370 - 1580 | 1590 - 1780 | 1590 - 1780 | 1790 - 1990 | 1790 - 1990 | - | 40 |

| 3.40 < d ≤ 3.60 | 1350 - 1560 | 1570 - 1760 | 1570 - 1760 | 1770 - 1970 | 1770 - 1970 | - | 40 |

| 3.60 < d ≤ 3.80 | 1340 - 1540 | 1550 - 1740 | 1550 - 1740 | 1750 - 1950 | 1750 - 1950 | - | 40 |

| 3.80 < d ≤ 4.00 | 1320 - 1520 | 1530 - 1730 | 1530 - 1730 | 1740 - 1930 | 1740 - 1930 | - | 35 |

| 4.00 < d ≤ 4.25 | 1310 - 1500 | 1510 - 1700 | 1510 - 1700 | 1710 - 1900 | 1710 - 1900 | - | 35 |

| 4.25 < d ≤ 4.50 | 1290 - 1490 | 1500 - 1680 | 1500 - 1680 | 1690 - 1880 | 1690 - 1880 | - | 35 |

| 4.50 < d ≤ 4.75 | 1270 - 1470 | 1480 - 1670 | 1480 - 1670 | 1680 - 1860 | 1680 - 1860 | - | 35 |

| 4.75 < d ≤ 5.00 | 1260 - 1450 | 1460 - 1650 | 1460 - 1650 | 1660 - 1840 | 1660 - 1840 | - | 35 |

| 5.00 < d ≤ 5.30 | 1240 - 1430 | 1440 - 1630 | 1440 - 1630 | 1640 - 1820 | 1640 - 1820 | - | 35 |

| 5.30 < d ≤ 5.60 | 1230 - 1420 | 1430 - 1610 | 1430 - 1610 | 1620 - 1800 | 1620 - 1800 | - | 35 |

| 5.60 < d ≤ 6.00 | 1210 - 1390 | 1400 - 1580 | 1400 - 1580 | 1590 - 1770 | 1590 - 1770 | - | 35 |

| 6.00 < d ≤ 6.30 | 1190 - 1380 | 1390 - 1560 | 1390 - 1560 | 1570 - 1750 | 1570 - 1750 | - | 35 |

| 6.30 < d ≤ 6.50 | 1180 - 1370 | 1380 - 1550 | 1380 - 1550 | 1560 - 1740 | 1560 - 1740 | - | 35 |

| 6.50 < d ≤ 7.00 | 1160 - 1340 | 1350 - 1530 | 1350 - 1530 | 1540 - 1710 | 1540 - 1710 | - | 35 |

| 7.00 < d ≤ 7.50 | 1140 - 1320 | 1330 - 1500 | 1330 - 1500 | 1510 - 1680 | 1510 - 1680 | - | 30 |

| 7.50 < d ≤ 8.00 | 1120 - 1300 | 1310 - 1480 | 1310 - 1480 | 1490 - 1660 | 1490 - 1660 | - | 30 |

| 8.00 < d ≤ 8.50 | 1110 - 1280 | 1290 - 1460 | 1290 - 1460 | 1470 - 1630 | 1470 - 1630 | - | 30 |

| 8.50 < d ≤ 9.00 | 1090 - 1260 | 1270 - 1440 | 1270 - 1440 | 1450 - 1610 | 1450 - 1610 | - | 30 |

| 9.00 < d ≤ 9.50 | 1070 - 1250 | 1260 - 1420 | 1260 - 1420 | 1430 - 1590 | 1430 - 1590 | - | 30 |

| 9.50 < d ≤ 10.00 | 1060 - 1230 | 1240 - 1400 | 1240 - 1400 | 1410 - 1570 | 1410 - 1570 | - | 30 |

| 10.00 < d ≤ 10.50 | - | 1220 - 1380 | 1220 - 1380 | 1390 - 1550 | 1390 - 1550 | - | 30 |

| 10.50 < d ≤ 11.00 | - | 1210 - 1370 | 1210 - 1370 | 1380 - 1530 | 1380 - 1530 | - | 30 |

| 11.00 < d ≤ 12.00 | - | 1180 - 1340 | 1180 - 1340 | 1350 - 1500 | 1350 - 1500 | - | 30 |

| 12.00 < d ≤ 12.50 | - | 1170 - 1320 | 1170 - 1320 | 1130 - 1480 | 1130 - 1480 | - | 28 |

| 12.50 < d ≤ 13.00 | - | 1160 - 1310 | 1160 - 1310 | 1320 - 1470 | 1320 - 1470 | - | 28 |

| 13.00 < d ≤ 14.00 | - | 1130 - 1280 | 1130 - 1280 | 1290 - 1440 | 1290 - 1440 | - | 28 |

| 14.00 < d ≤ 15.00 | - | 1160 - 1260 | 1160 - 1260 | 1270 - 1410 | 1270 - 1410 | - | 28 |

| 15.00 < d ≤ 16.00 | - | 1090 - 1230 | 1090 - 1230 | 1240 - 1390 | 1240 - 1390 | - | 28 |

| 16.00 < d ≤ 17.00 | - | 1070 - 1210 | 1070 - 1210 | 1220 - 1360 | 1220 - 1360 | - | 28 |

| 17.00 < d ≤ 18.00 | - | 1050 - 1190 | 1050 - 1190 | 1200 - 1340 | 1200 - 1340 | - | 28 |

| 18.00 < d ≤ 19.00 | - | 1030 - 1170 | 1030 - 1170 | 1180 - 1320 | 1180 - 1320 | - | 28 |

| 19.00 < d ≤ 20.00 | - | 1020 - 1150 | 1020 - 1150 | 1160 - 1300 | 1160 - 1300 | - | 28 |

1) The values listed in DIN 17223:1964 were given in kg/mm2; the conversion performed is for guidance purposes.

PERMISSIBLE TENSILE STRENGTH RANGE (MPa) IN A SINGLE PACKAGE EN 10270-1:2011

| Nominal diameter d mm | SL, SM, SH | DM, DH |

| d < 0.80 | 150 | 150 |

| 0.80 ≤ d < 1.60 | 120 | 100 |

| 1.60 ≤ d | 120 | 70 |

The requirements are applicable to unit packages in which the mass in kilogrammes is not greater than the value 250 x d (d = wire diameter in mm) or a value of 1000 kg. In the case of coils with a higher mass, appropriate arrangements must be agreed.

Coatings subject to Standards:

| Coating | Description | |

| Phosphated | ph | The wire is treated in a solution so that a layer of phosphated metal forms on its surface. |

| Galvanising | Z | The surface is coated in a layer of zinc. |

| Zinc - Aluminium | ZA | The surface is coated in a layer of Zn 95 / Al 5(%) |

| Reddish | rd | The surface is coated with a thin layer of copper, normally a conversion coating. |

| Coppery | Cu | The surface is coated in a thick (even) layer of copper |

MINIMUM COATING DENSITY REQUIRED OF ZINC OR ZINC/ALUMINIUM EN 10270-1

| Nominal diameter d mm | Minimum coating density a) b) g/m² |

| 0.20 ≤ d < 0.25 | 20 |

| 0.25 ≤ d < 0.40 | 25 |

| 0.40 ≤ d < 0.50 | 30 |

| 0.50 ≤ d < 0.60 | 35 |

| 0.60 ≤ d < 0.70 | 40 |

| 0.70 ≤ d < 0.80 | 45 |

| 0.80 ≤ d < 0.90 | 50 |

| 0.90 ≤ d < 1.00 | 55 |

| 1.00 ≤ d < 1.20 | 60 |

| 1.20 ≤ d < 1.40 | 65 |

| 1.40 ≤ d < 1.65 | 70 |

| 1.65 ≤ d < 1.85 | 75 |

| 1.85 ≤ d < 2.15 | 80 |

| 2.15 ≤ d < 2.50 | 85 |

| 2.50 ≤ d < 2.80 | 95 |

| 2.80 ≤ d < 3.20 | 100 |

| 3.20 ≤ d < 3.80 | 105 |

| 3.80 ≤ d < 10.00 | 110 |

a) The requirements regarding zinc coatings fall within class C in Standard EN 10244-2:2009.

b) If different coating weights are required, priority will be given to the reference coating weights established in Standard En 10244-2 (for example: class D of standard En 10244-2:2009).

SALT SPRAY TEST

| GALVANISED COATING | Zn - Al COATING | ||

| Exposure time (hours) | Density of Zn (g/m2) | Exposure time (hours) | Density of Zn - Al (g/m2) |

| 36 | 80 | - | - |

| 48 | 90 | 120 | >40 |

| 72 | 105 | 240 | >60 |

| 96 | 125 | 264 | >75 |

| 120 | 165 | 288 | >85 |

| 144 | 195 | 312 | >100 |

| 168 | 220 | 360 | >110 |

| 192 | 240 | 408 | >125 |

Diameter tolerances. Permissible deviations according to EN 10270-1

| Diameter of the wire d | |

| Nominal value mm | Permissible deviations mm |

| 0.05 < d ≤ 0.09 | ± 0.003 |

| 0.09 < d ≤ 0.16 | ± 0.004 |

| 0.16 < d ≤ 0.25 | ± 0.005 |

| 0.25 < d ≤ 0.63 | ± 0.008 |

| 0.63 < d ≤ 0.75 | ± 0.010 |

| 0.75 < d ≤ 1.00 | ± 0.015 |

| 1.00 < d ≤ 1.20 | ± 0.020 |

| 1.20 < d ≤ 1.70 | ± 0.020 |

| 1.70 < d ≤ 2.60 | ± 0.025 |

| 2.60 < d ≤ 4.00 | ± 0.030 |

| 4.00 < d ≤ 5.30 | ± 0.035 |

| 5.30 < d ≤ 7.00 | ± 0.040 |

| 7.00 < d ≤ 9.00 | ± 0.045 |

| 9.00 < d ≤ 10.00 | ± 0.050 |

| 10.00 < d ≤ 11.00 | ± 0.070 |

| 11.00 < d ≤ 14.00 | ± 0.080 |

| 14.00 < d ≤ 18.00 | ± 0.090 |

| 18.00 < d ≤ 20.00 | ± 0.100 |

OVALITY

WHEN SUPPLIED IN RODS. Straightened wire:

| Nominal diameter d mm | Diameter tolerance a) mm | Supply capacity b) mm. | ||

| Lower tolerance | Higher tolerance | Minimum length | Maximum length | |

| 0.65 ≤ d < 0.80 | -0.010 | +0.022 | 50 | 2000 |

| 0.80 ≤ d < 1.01 | -0.015 | +0,030 | 30 | 2000 |

| 1.01 ≤ d < 1.35 | -0.020 | +0,040 | ||

| 1.35 ≤ d < 1.78 | -0.020 | +0,045 | ||

| 1.78 ≤ d < 2.01 | -0.025 | +0,055 | ||

| 2.01 ≤ d < 2.35 | -0.025 | +0,060 | 30 | 4000 |

| 2.35 ≤ d < 2.78 | -0.025 | +0,065 | ||

| 2.78 ≤ d < 3.01 | -0.030 | +0,075 | ||

| 3.01 ≤ d < 3.35 | -0.030 | +0,080 | 30 | 4000 |

| 3.35 ≤ d < 4.01 | -0.030 | +0,090 | ||

| 4.01 ≤ d < 4.35 | -0.035 | +0,100 | ||

| 4.35 ≤ d < 5.01 | -0.035 | +0,110 | 30 | 4350 |

| 5.01 ≤ d < 5.45 | -0.035 | +0,120 | ||

| 5.45 ≤ d < 6.01 | -0.040 | +0,130 | ||

| 6.01 ≤ d < 7.12 | -0.040 | +0.150 | 250 | 4350 |

| 7.12 ≤ d < 7.67 | -0.045 | +0,160 | ||

| 7.67 ≤ d < 9.01 | -0.045 | +0,180 | ||

| 9.01 ≤ d < 10.01 | -0.050 | +0,200 | ||

| 10.01 ≤ d < 10.50 | -0.070 | +0,240 | ||

a) Diameter tolerances of straightened and cut lengths according to EN 10270-1

b) Approximate data for information purposes.

STANDARD LENGTH TOLERANCES

| NOMINAL LENGTH | TOLERANCE |

| L < = 1000 mm. | +/- 1 mm. |

| 1000 < L < = 4000 | - 0mm. / +3 mm. |

The global electric vehicle (EV) market is experiencing significant growth, driven by a number of...

The global electric vehicle (EV) market is experiencing significant growth, driven by a number of...