Oil Tempered Steel Wire

CHEMICAL COMPOSITION - Steel Tempered in Oil and Quenched for Mechanical Springs EN 10270-2

| Chemical composition mass % | |||||||||

| EN | C | Si | Mn | P | S | Cu | Cr | V | |

| DESIG. | STANDARD | % | % | % | max. % | max. % | max. % | % | % |

| FDC | EN 10270-2 | 0.60-0.75 | 0.10-0.35 | 0.50-1.20 | 0.03 | 0.025 | 0.12 | - | - |

| FDSiCr | EN 10270-2 | 0.50-0.60 | 1.20-1.60 | 0.50-0.90 | 0.03 | 0.025 | 0.12 | 0.50-0.80 | - |

| FDSiCrV | EN 10270-2 | 0.50-0.70 | 1.20-1.65 | 0.40-0.90 | 0.03 | 0.025 | 0.12 | 0.50-1.00 | 0.10-0.25 |

| TDSiCr | EN 10270-2 | 0.50-0.60 | 1.20-1.60 | 0.50-0.90 | 0.025 | 0.02 | 0.1 | 0.50-0.80 | - |

| TDSiCrV | EN 10270-2 | 0.50-0.70 | 1.20-1.65 | 0.40-0.90 | 0.02 | 0.02 | 0.1 | 0.50-1.00 | 0.10-0.25 |

| VDSiCr | EN 10270-2 | 0.50-0.60 | 1.20-1.60 | 0.50-0.90 | 0.025 | 0.02 | 0.06 | 0.50-0.80 | - |

| VDSiCrV | EN 10270-2 | 0.50-0.70 | 1.20-1.65 | 0.40-0.90 | 0.02 | 0.02 | 0.06 | 0.50-1.00 | 0.10-0.25 |

Wire rods used for TD and VD, with few impurities present

OIL-HARDENED STEEL WIRE: INCREASED HARDNESS AND TOUGHNESS

MECHANICAL CHARACTERISTICS AND SPECIFICATIONS

Oil tempered steel wire is achieved by heating the workpiece to a high temperature and then cooling it in an oil bath. This hardens the material and improves its resistance to deformation and abrasion. At VINCO we have available a wide range of chemical compositions of quenched and tempered steel wire based on the EN 10270-2 standard which applies to quenched and tempered spring steel wires.

In the mechanical characteristics section of the product data sheet you can find out what each type of hardened steel wire is used for, as well as the tensile strength of all of them. The inner and outer diameter measurements and the weight of the coil according to the nominal value in millimetres are also detailed.

PACKAGING OPTIONS FOR THE SUPPLY OF HARDENED STEEL WIRE

The following table details the different packaging options according to the maximum weight that we offer you:

| Type of packaginge | Maximum weight in kg |

| Roll | 500 |

| Sling Bar / Carrier | 2000 |

| Coil Z | 800 |

| Metallic reel DIN 560 G200/32 | 150 |

| Metallic reel G200/40 | 150 |

| Metallic reel G240/40 | 300 |

| Wooden reel G240/40 | 300 |

| Rods | - |

In addition to these types of packaging, in the supply of oil-hardened steel wire we offer different possibilities to adapt to the needs of each customer, such as the type of palletisation - square or round - and the orientation of the coil axis - horizontal or vertical axis. Along with these packaging and supply options, at VINCO we have different protection elements to preserve all the properties of our wires during the shipping process: cover, VCI damp-proof paper, VCI damp-proof plastic, phytosanitary packaging, maritime packaging and damp-proof sacks.

FINISHES AND TOLERANCES

In order to determine the finish of the oil-hardened steel wire, a number of properties to be defined at the time of ordering must be taken into account:

- Surface quality of the material according to EN 10270-1 which applies to mechanical spring steel wires.

- Permissible depth for surface defects depending on the type of wire.

- Surface defects determined by the Eddie-current test using electromagnetic currents on a non-destructive basis.

- Surface decarburisation measured in millimetres.

- Shave on request.

On the other hand, in the tolerances section of the technical data sheet we have detailed, according to the wire diameter, the nominal value in millimetres and the admissible deviations registered in the EN 10270-2 Standard. The ovality is another aspect to be taken into account, which must not exceed 50% of the total admissible deviation. Finally, the standard length tolerances are also specified in the same section. Consult our complete technical data sheet and get all the information you need.

| Approximate equivalent | ||||

| EN | US (AISI) | Japan (JIS) | CHINESE | |

| DESIG. | STANDARD | ASTM | JIS G3560 | GB / T 18983 |

| FDC | EN 10270-2 | A 229 | SWO-A B | FDC |

| FDSiCr | EN 10270-2 | A 401 | SWOSC-B | FDCrSi |

| FDSiCrV | EN 10270-2 | - | - | - |

| TDSiCr | EN 10270-2 | A 1000-5 Grade A | - | TDCrSi |

| TDSiCrV | EN 10270-2 | 2 A 1000-5 Grade D | - | - |

| VDSiCr | EN 10270-2 | A 877 | SWOSC-V | VDCrSi |

| VDSiCrV | EN 10270-2 | - | - | - |

MECHANICAL PROPERTIES

| Diameter of the wire | Tensile strength Rm (N/mm2) | ||||||

| Nominal value mm | FDC | FDSiCr | FDSiCrV | TDSiCr | TDSiCrV | VDSiCr | VDSiCrV |

| 0.50 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.55 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.60 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.65 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.70 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.75 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.80 | 1900-2100 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.85 | 1860-2060 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.90 | 1860-2060 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 0.95 | 1860-2060 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.00 | 1860-2060 | 2100-2300 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.05 | 1810-2010 | 2070-2260 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.10 | 1810-2010 | 2070-2260 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.20 | 1810-2010 | 2070-2260 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.30 | 1810-2010 | 2070-2260 | 2280-2430 | 2080-2230 | 2230-2380 | 2080-2230 | 2230-2380 |

| 1.40 | 1790-1970 | 2060-2250 | 2260-2410 | 2060-2210 | 2210-2360 | 2060-2210 | 2210-2360 |

| 1.50 | 1760-1940 | 2040-2220 | 2260-2410 | 2060-2210 | 2210-2360 | 2060-2210 | 2210-2360 |

| 1.60 | 1760-1940 | 2040-2220 | 2260-2410 | 2060-2210 | 2210-2360 | 2060-2210 | 2210-2360 |

| 1.70 | 1730-1890 | 2000-2180 | 2210-2360 | 2010-2160 | 2130-2310 | 2010-2160 | 2130-2310 |

| 1.80 | 1730-1890 | 2000-2180 | 2210-2360 | 2010-2160 | 2130-2310 | 2010-2160 | 2130-2310 |

| 1.90 | 1730-1890 | 2000-2180 | 2210-2360 | 2010-2160 | 2130-2310 | 2010-2160 | 2130-2310 |

| 2.00 | 1730-1890 | 2000-2180 | 2210-2360 | 2010-2160 | 2130-2310 | 2010-2160 | 2130-2310 |

| 2.25 | 1670-1820 | 1970-2140 | 2160-2310 | 1960-2060 | 2100-2250 | 1960-2060 | 2100-2250 |

| 2.50 | 1670-1820 | 1970-2140 | 2160-2310 | 1960-2060 | 2100-2250 | 1960-2060 | 2100-2250 |

| 2.70 | 1640-1790 | 1950-2120 | 2110-2260 | 1910-2010 | 2060-2210 | 1910-2010 | 2060-2210 |

| 3.00 | 1620-1770 | 1930-2100 | 2110-2260 | 1910-2010 | 2060-2210 | 1910-2010 | 2060-2210 |

| 3.20 | 1600-1750 | 1910-2080 | 2110-2260 | 1910-2010 | 2060-2210 | 1910-2010 | 2060-2210 |

| 3.50 | 1580-1730 | 1900-2060 | 2110-2260 | 1910-2010 | 2010-2160 | 1910-2010 | 2010-2160 |

| 4.00 | 1550-1700 | 1870-2030 | 2060-2210 | 1860-1960 | 2010-2160 | 1860-1960 | 2010-2160 |

| 4.20 | 1540-1690 | 1860-2020 | 2060-2210 | 1860-1960 | 1960-2110 | 1860-1960 | 1960-2110 |

| 4.50 | 1520-1670 | 1850-2000 | 2060-2210 | 1860-1960 | 1960-2110 | 1860-1960 | 1960-2110 |

| 4.70 | 1510-1660 | 1840-1990 | 2010-2160 | 1810-1910 | 1960-2111 | 1810-1910 | 1960-2111 |

| 5.00 | 1500-1650 | 1830-1980 | 2010-2160 | 1810-1910 | 1690-2110 | 1810-1910 | 1690-2110 |

| 5.60 | 1470-1620 | 1800-1950 | 2010-2160 | 1810-1910 | 1910-2060 | 1810-1910 | 1910-2060 |

| 6.00 | 1460-1610 | 1780-1930 | 1960-2110 | 1760-1860 | 1910-2060 | 1760-1860 | 1910-2060 |

| 6.50 | 1440-1590 | 1760-1910 | 1960-2110 | 1760-1860 | 1910-2060 | 1760-1860 | 1910-2060 |

| 7.00 | 1430-1580 | 1740-1890 | 1960-2110 | 1710-1810 | 1860-2010 | 1710-1810 | 1860-2010 |

| 7.50 | 1400-1550 | 1710-1860 | 1910-2050 | 1710-1810 | 1680-2010 | 1710-1810 | 1680-2010 |

| 8.00 | 1400-1550 | 1710-1860 | 1910-2050 | 1710-1810 | 1680-2010 | 1710-1810 | 1680-2010 |

| 8.50 | 1380-1530 | 1700-1850 | 1890-2030 | 1670-1770 | 1810-1960 | 1670-1770 | 1810-1960 |

| 9.00 | 1360-1510 | 1660-1810 | 1870-2010 | 1670-1770 | 1810-1960 | 1670-1770 | 1810-1960 |

| 9.50 | 1360-1510 | 1660-1810 | 1870-2010 | 1670-1770 | 1810-1960 | 1670-1770 | 1810-1960 |

| 10.00 | 1360-1510 | 1660-1810 | 1870-2010 | 1670-1770 | 1810-1910 | 1670-1770 | 1810-1960 |

| 11.00 | 1320-1470 | 1620-1770 | 1830-1970 | * | * | * | * |

| 12.00 | 1320-1470 | 1620-1770 | 1830-1970 | * | * | * | * |

| 13.00 | 1280-1430 | 1580-1730 | 1790-1930 | * | * | * | * |

| 14.00 | 1280-1413 | 1580-1730 | 1790-1930 | * | * | * | * |

| 15.00 | 1270-1420 | 1570-1720 | 1780-1920 | * | * | * | * |

| 16.00 | 1250-1400 | 1550-1700 | 1760-1900 | * | * | * | * |

| 17.00 | 1250-1400 | 1550-1700 | 1760-1900 | * | * | * | * |

* Under a commercial agreement.

USE OF DIFFERENT TYPES OF WIRE

| TYPE | DESCRIPTION |

| FDC | Suitable for static applications. |

| FDSiCr | |

| FDSiCrV | |

| TDSiCr | Steel wire for springs with medium fatigue levels, such as that required for alloy and non-alloy steel clutch springs. |

| TDSiCrV | |

| VDSiCr | Wire for alloy and non-alloy steel springs for use with severe dynamic stresses, such as springs for valves. |

| VDSiCrV |

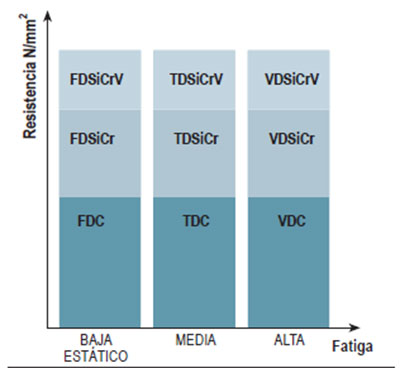

Tensile Strength (N/mm2) Vs Fatigue

* SOURCE STANDARD EN 10270-2

| Tensile strength | Static | Medium fatigue | High fatigue |

| Low | FDC | TDC | VDC |

| Medium | FDCrV | TDCrV | VDCrV |

| High | FDSiCr | TDSiCr | VDSiCr |

| Very high | FDSiCrV | TDSiCrV | VDSiCrV |

CONDITIONING

| Nominal value mm. | Inner diameter (approx.) | Outer diameter (approx.) | Weight of the roll |

| 0,8 ~ 1.99 | 550 ~ 650 | 900 ~ 1000 | 300 |

| 1,5 ~ 4,99 | 680 ~ 1050 | 1150 ~ 1450 | 1000 |

| 5.00 ~ 8.00 | 950 ~ 1400 | 1350 ~ 1850 | 1000 |

| 8.00 ~ 16.00 | 1800 | 2300 | 1000-2000 |

The material can be placed on racks and, if so, more than one roll per rack.

The rolls unwind in an ANTI-CLOCKWISE direction.

Diameters below 1.40mm and above 16.0mm on request

Surface quality EN 10270-1

Permissible depth of surface defects

| Type of wire | VD | TD | FD |

| C | 0.005 d | 0.008 d | 0.010 d |

| SiCr, SiCrV | 0.010 d | 0.013 d | 0.015 d |

Permissible surface defects through Foucault current test (Eddy Current Test).

| Nominal diameter d | Maximum depth of the defect a) | |

| mm | VD | TD |

| 2.50 ≤ d ≤ 4.99 | 40 µm | 60 µm |

| 4.99 ≤ d ≤ 5.99 | 50 µm | 60 µm |

| 5.99 ≤ d ≤ 8.00 | 60 µm | 0.01 d |

a) ECT also possible for FD quality and diameters 8mm-16mm under a commercial agreement.

Surface decarburisation

| Type of wire | VD | TD | FD |

| C | 0.005 d | 0.008 d | 0.010 d |

| SiCr, SiCrV | 0.010 d | 0.013 d | 0.015 d |

We are able to supply special qualities and qualities not covered by any standards, under a commercial agreement.

TRIMMING

| FDC | On request |

| FDSiCr | On request |

| FDSiCrV | On request |

| TDSiCr | On request |

| TDSiCrV | On request |

| VDSiCr | <2.5mm on request |

| VDSiCrV | <2.5mm on request |

Diameter tolerances. Permissible deviations according to EN 10270-2

| DIAMETER OF THE WIRE | |

| Nominal value mm | Permissible deviations |

| 0.50 ≤ d < 0.85 | +/- 0.010 |

| 0.85 ≤ d < 1.05 | +/- 0.015 |

| 1.05 ≤ d < 1.70 | +/- 0.020 |

| 1.70 ≤ d < 3.00 | +/- 0.025 |

| 3.00 ≤ d < 4.20 | +/- 0.030 |

| 4.20 ≤ d < 6.00 | +/- 0.035 |

| 6.00 ≤ d < 7.50 | +/- 0.040 |

| 7.50 ≤ d < 9.00 | +/- 0.045 |

| 9.00 ≤ d < 11.00 | +/- 0.050 |

| 11.00 ≤ d < 13.00 | +/- 0.070 |

| 13.00 ≤ d < 16.00 | +/- 0.080 |

| 16.00 ≤ d ≤ 17.00 | +/- 0.090 |

OVALITY

LENGTH TOLERANCES OF THE CUT LENGTHS

| NOMINAL LENGTH | TOLERANCE |

| L < = 1000 mm. | +/- 1 mm. |

| 1000 < L < = 4000 | - 0mm. / +3 mm. |

The global electric vehicle (EV) market is experiencing significant growth, driven by a number of...

The global electric vehicle (EV) market is experiencing significant growth, driven by a number of...