OPTIMISATION OF THE CLIENT SUPPLY CHAIN WITH THE PREMIUM CUTTING MODE

Value proposal: To reduce client cycle times.

BENEFITS OF PREMIUM STRIP CUTTING

Savings on the client production process.

Better response to the automation of production processes.

Optimisation of staff resources.

Increased productivity.

Sustainability.

Immediate response to the market needs.

Lower storage costs.

Better quality outcome.

PRODUCTION CAPACITIES

Widths from 3mm and thicknesses from 0.05mm across a wide range of products in terms of sizes, quantities, formats, surface finishes, coatings, etc.

*Check availability with your VINCO sales representative or send us an email: info@vinco.es

AVAILABLE STOCK

We have a wide range of strips in stock, all specially selected to offer you a premium cut to the size you need, with no marks or surface defects.

PRODUCTION CAPACITIES

Widths from 3mm and thicknesses from 0.05mm across a wide range of products in terms of sizes, quantities, formats, surface finishes, coatings, etc.

*Check availability with your VINCO sales representative or send us an email: info@vinco.es

AVAILABLE STOCK

We have a wide range of strips in stock, all specially selected to offer you a premium cut to the size you need, with no marks or surface defects.

VINCO, AT THE TECHNOLOGICAL FOREFRONT OF INTERNATIONAL PREMIUM CUT STRIP SUPPLY, TAILORS ITS PRODUCTION TO EACH CLIENT

It has been a long time since Global companies understood the benefits of achieving these competitive benefits, increasing their operational capacity and brand image to the detriment of those who have focused their efforts in search of other values, such as cost.

VINCO’s philosophy has always been to help the aforementioned, focusing not only on offering top quality materials, but also on supporting its clients throughout the development of their projects and the purchasing process. The company, part of the Lontana group, has a presence and representatives in 100 countries across a wide range of sectors, as well as decades of experience offering global solutions adapted to the needs of its clients.

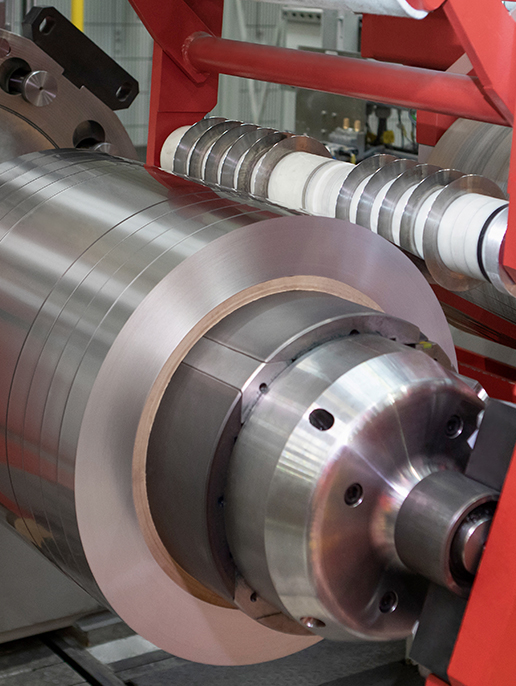

Perhaps where the ability to tailor and personalise materials to specific client requirements stands out the most is in the premium cut, which enables materials to be cut very accurately, avoiding surface defects.

Such development is only achieved by VINCO ability to make a delicate cut that avoids surface defects in materials ranging from bright stainless steel, copper and copper alloy strip and strip with surface finishes and coatings.

How do we do it?

VINCO’s premium cutting service provides the solution to supplying material with a mark free surface finish, thus reducing waste in the client production line and helping to increase their productivity.

Having reliable suppliers that guarantee the supply of materials without marks and with perfect surface finishes is a competitive advantage for all industrial manufacturing companies where marked material can lead to a loss of resources and, ultimately, personnel costs and material wastage. Have you ever faced this challenge?

VINCO, a company specialised in the supply of Strips, Wires and Wire Rope, has years of expertise, offering guaranteed supply, in addition to a holistic guidance, support and customisation service tailored to each client. In response to this, it has developed a solution that is of particular relevance in the stamping, electronics and automotive sectors, among others.

Marks and scratches on metal strips lead to waste - have you ever faced this challenge?

One of the company’s main values and intentions consists of reinforcing the service guarantee and quality product, understanding each customer as being unique and accompanying them throughout the purchasing process, thus becoming a trusted agent and collaborator for the companies, giving them satisfaction and guarantees that would be difficult to achieve by any other means

Perhaps the best example of how VINCO collaborates with its clients, practically becoming their partner, is its ability to offer a supply of the necessary material, free of marks and surface defects, at the time and in the quantity the client requires.

The result of this is a symbiosis in which the client’s supply chain is integrated and ready to attract new projects, reducing the risk of speculation with the value of raw materials in a market as changeable as that which we are currently experiencing.

With the new cutting lines for delicate materials, at VINCO’s cutting centre we can process the sensitive surface finish strip carefully and accurately in order to provide you with scratch and mark free material in thicknesses from 0.05mm and whatever width you need.